Free Case Study

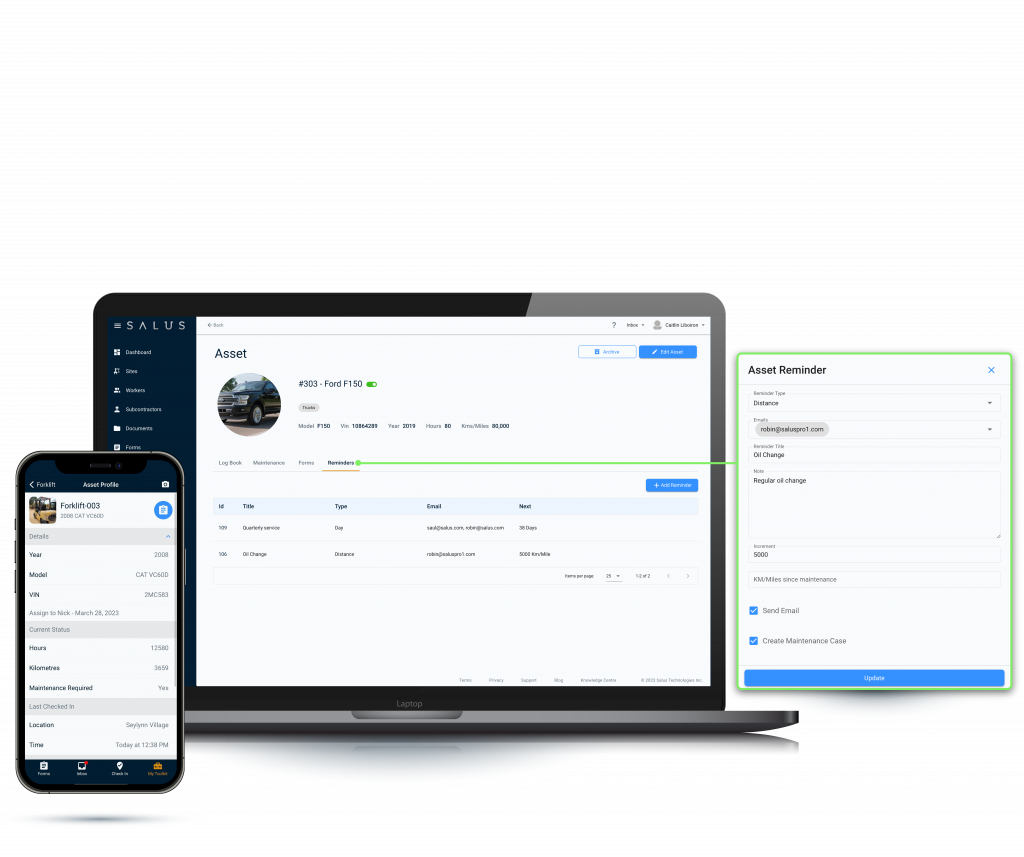

HOW ELIMINATING PAPER FORMS SAVED STAMPEDE ELECTRIC TIME AND MONEY

We interviewed Jenny Buck, Executive Assistant at Stampede Electric, to learn about their transition from paper-based safety documentation to a comprehensive and centralized safety management platform.

Digital safety has given Jenny and her team:

- More time to focus on high priority tasks

- Better organization and management of their safety documentation

- Ability to easily train and onboard new workers